The science of cultivated meat

Learn about the science of cultivated meat and the challenges that must be addressed for commercial production.

What is cultivated meat?

Cultivated meat, also known as cultured meat, is genuine animal meat (including seafood and organ meats) produced by cultivating animal cells in a safe and controlled environment. The end product is nutritionally comparable to conventional meat, allowing us to feed more people with fewer resources and meet the growing global demand for protein in a more humane way.

Dutch scientist Mark Post unveiled the first cultivated meat burger on live television in 2013. Two years later, the first four companies were founded. As of 2024, the industry has grown to over 175 companies on six continents, backed by over $3.1 billion in investments. Each company aims to produce cultivated meat products or offer technology solutions along the value chain.

Decades of accumulated knowledge in cell culture, stem cell biology, tissue engineering, fermentation, and chemical and bioprocess engineering preceded the field of cultivated meat. Hundreds of companies and academic laboratories worldwide are conducting research across these disciplines to establish a new paradigm for manufacturing commodity meat products at industrial scales.

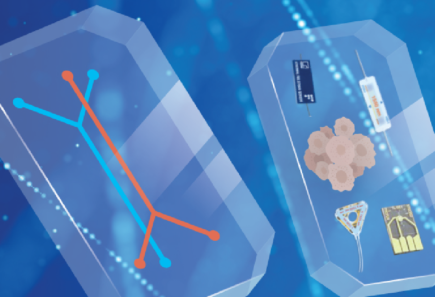

How is cultivated meat made?

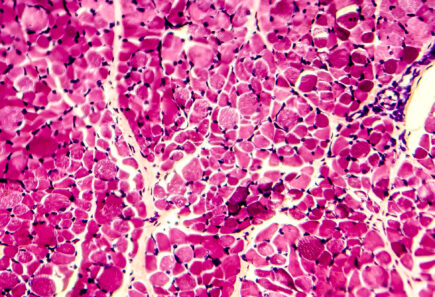

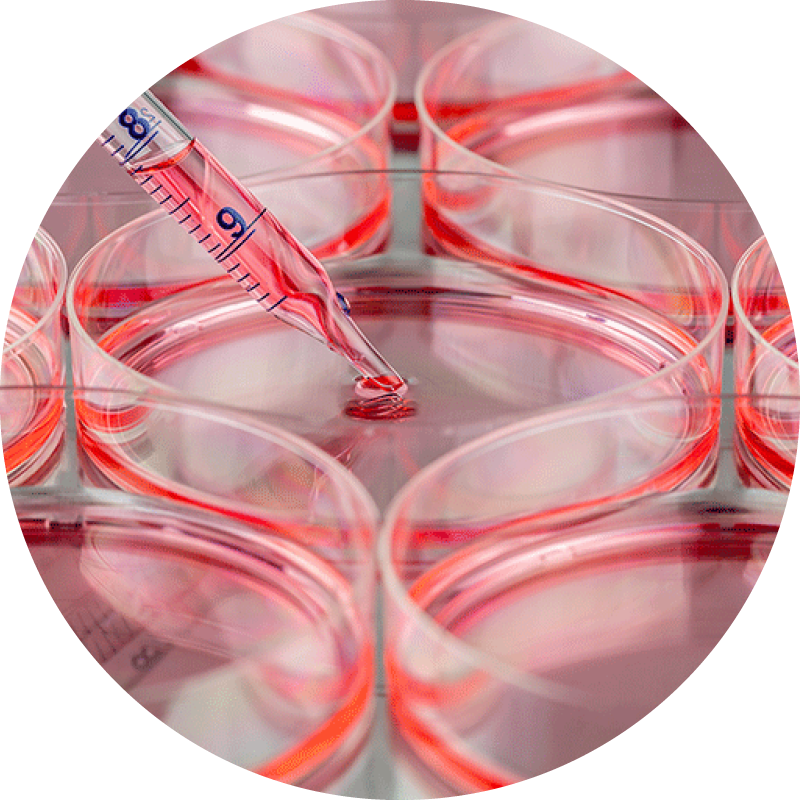

The manufacturing process begins with acquiring and banking stem cells from an animal. These cells are then grown in bioreactors (known colloquially as cultivators) at high densities and volumes. The cells are fed an oxygen-rich cell culture medium containing basic nutrients such as amino acids, glucose, vitamins, and inorganic salts, and typically supplemented with growth factors and other proteins.

Changes in the medium composition, often in tandem with cues from a scaffolding structure, trigger immature cells to differentiate into the skeletal muscle, fat, and connective tissues that make up meat. The differentiated cells are then harvested, prepared, and packaged into final products. This process is expected to take two to eight weeks, depending on the kind of meat being cultivated. Some companies are pursuing a similar strategy to create milk and other animal products.

What are the benefits of cultivated meat?

Cultivated meat is expected to have numerous benefits over conventional animal agriculture by nature of its controlled and more efficient production process. Prospective life cycle assessments indicate that cultivated meat will use significantly fewer resources and can reduce agriculture-related pollution and eutrophication. One study showed that if produced using renewable energy, cultivated meat could reduce greenhouse gas emissions by up to 92 percent and land use by up to 90 percent compared to conventional beef. Additionally, it’s expected that antibiotics will not be used in production (as of 2024, all approved products are manufactured without antibiotics) and will likely result in fewer incidences of foodborne illnesses due to the lack of exposure risk from enteric pathogens.

Over the next few decades, cultivated meat and other alternative proteins are predicted to take significant market share from the $1.7 trillion conventional meat and seafood industries. This shift could mitigate agriculture-related deforestation, biodiversity loss, antibiotic resistance, and zoonotic disease outbreaks.

When will cultivated meat make it to market?

Cultivated meat has been approved for sale in a few regions, but its availability is still limited in geography and production volume. Additional regulatory approvals and solutions to scaling challenges are needed to bring cultivated meat to a broader range of consumers.

Several leading cultivated meat companies are transitioning to pilot-scale facilities that will manufacture the first wave of commercialized products following regulatory approval. In December 2020, the Singapore Food Agency approved the world’s first cultivated chicken product for sale, and a hybrid version of the product is currently sold at a local retailer.

In November 2022, UPSIDE Foods completed the first pre-market consultation for its cultivated chicken product with the United States Food and Drug Administration (FDA). In June 2023, both UPSIDE Foods and GOOD Meat acquired inspection grants from the United States Department of Agriculture (USDA), allowing them to sell their cultivated chicken to consumers in the United States.

In 2024, Israel’s Ministry of Health approved the first cultivated beef product produced by Aleph Farms, but additional regulatory steps remain (inspection and labeling) prior to it being sold in Israel. The Singapore Food Agency approved cultivated quail produced by Vow, bringing the total number of cultivated meat products to pass rigorous safety evaluations to four. In November 2024, Vow’s product briefly debuted in Hong Kong. Additionally, in July 2024, Meatly was cleared to sell cultivated chicken as pet food in the UK.

As of the end of 2024, additional cultivated meat products are under regulatory review in ten countries or regions, including the United States, the European Union, Singapore, Israel, Australia and New Zealand, Switzerland, the United Kingdom, Thailand, and South Korea. Other countries are at various stages of developing regulatory frameworks to permit the sale of cultivated meat.

Further scaling will require commercial production in significantly larger facilities than what currently exists. Scaling will also require solving an array of complex challenges that will influence the cost of production. These challenges span five key areas: cell lines, cell culture media, bioprocess design, scaffolding, and end product design and characterization.

Solving these challenges and propelling the cultivated meat industry to maturity will require an influx of public and private sector funding. New courses, research centers, and training programs for scientists, as well as policy work and regulatory action, will accelerate progress. The field will also need new companies, contributions from existing food and life science companies, and openness to collaboration from other cultivated meat companies. Talented scientists, businesspeople, and other contributors along the value chain must fill many new career opportunities.

Cell lines

Many different cell types can be used to cultivate meat. Further research is needed to make cell lines more accessible and to determine how the selection of a cell type and its properties influence the downstream process considerations.

The current state of cell lines

According to an industry survey conducted in 2023, cultivated meat manufacturers are using a variety of starter cells, including skeletal muscle stem cells (i.e., myosatellite cells), fibroblasts, mesenchymal stem cells, induced pluripotent and embryonic stem cells, and adipose-derived cells. Starter cells can also sometimes originate from specific organs to create other products. For example, cells from mammary glands can be used for milk production, and cells from livers for foie gras.

The most common method of acquiring starter cells is to take a cell sample from a live animal, which can be performed using minimally invasive methods. In some cases, these cells may also be acquired by biopsying a recently slaughtered animal where the tissue is still viable, which could be important for determining compliance with religious laws (e.g., halal, kosher). In all cases, the acquired cells originate from healthy animals alongside extensive documentation that ensures the quality and traceability of the cells.

Deriving cell lines requires many resources

Most cultivated meat manufacturers work with well-characterized cell lines that can continuously proliferate over time. Some producers may use primary cells, which, by definition, have a finite life span. Access to continuous cell lines from species used for cultivated meat production remains a major barrier to new research endeavors.

Creating new cell lines can be time- and resource-intensive, often taking 6-18 months to derive and sufficiently characterize a single line. In medical research, the creation of large-scale cell line biorepositories is often nationally sponsored, emphasizing their fundamental importance in advancing research. Similar government-backed projects for cultivated meat are underway in Singapore, but more are needed.

Increasing access to cell lines is a priority for the industry

To accelerate cell line availability, we are tracking available cell lines (nearly 75 as of 2024) and funding multiple research projects that create cell lines from species spanning livestock, poultry, and aquatic animals. B2B companies specializing in cell line creation and distribution are pursuing similar strategies.

Additional efforts are needed to generate and characterize cell lines from more species and different cell types, create protocols for cell isolation and culturing conditions, and discover low-cost, animal-free cell culture medium formulations. Partnerships with conventional meat producers and aquaculture groups that often work with animal cell lines may accelerate R&D in these areas.

Cell line challenges

Cell types have specific pros and cons

As described previously, many cell types can be used as starting inputs for cultivated meat production. However, more research is needed to determine which cells are best suited for large-scale manufacturing or creating specific product types. Intrinsic cell characteristics, such as suitability for suspension growth, doubling times, growth rates, metabolism, differentiation capacity, and genomic stability, can vary between cell types and species.

These characteristics must be weighed alongside techno-economic models and bioprocess design considerations to inform cell line selection. However, this is challenging. Species used in cultivated meat production (especially aquatic animals) are much less researched than humans, mice, or hamsters, which have been the mainstay of the biomedical and biopharmaceutical industries. Survey data indicate that the highest-priority cell types needing additional cell line development efforts are embryonic and induced pluripotent stem cells in the case of terrestrial animals, whereas myoblasts are a higher priority for aquatic species.

Engineering cells can inform research and development

Cell engineering can accelerate the development of cell lines suitable for cultivated meat. It can also dramatically improve the efficiency or productivity of the production process or even influence end product attributes such as nutrition.

Cell line engineering can take place through adaptation or genetic engineering. Adaptation involves the serial subculture of a cell line in varying conditions along with selection over time. This process yields a cell line adapted to a new set of conditions or exhibiting a new trait. Common forms of adaptation include adaptation to serum-free medium, reduced requirements for growth factors, or suspension growth.

Genetic engineering entails permanent changes by removing, rearranging, or introducing DNA. A 2023 survey found that nearly half of cultivated meat companies are exploring genetic engineering for either R&D or commercial use, and several patents describing various engineering approaches have been filed. Ultimately, the extent of genetic engineering and types of modifications incorporated into final products will depend on the regulatory approval process for engineered products and consumer perceptions in different regions.

What comes next for cell lines

Democratization of cell lines will open new doors

In the future, researchers will have easy access to many well-characterized cell lines housed in multiple biorepositories worldwide. To get there, more public funding is needed to attract experienced stem cell biologists who can apply their knowledge and tools to the cultivated meat field. Researchers and companies alike should be motivated and incentivized to deposit cell lines in public repositories to lower the burden of entry throughout the industry.

Life science companies and contract research organizations specializing in cell line development are needed to help overcome challenges in cell line engineering. These companies can apply high-throughput techniques and automation technologies to improve cell line R&D and engineering efforts. Together, these efforts can support a more robust research ecosystem that will generate new findings, create new tools, reduce costs, and accelerate the pace of commercialization.

Check out additional reading and resources

Discover papers, resources, ongoing research projects, and research opportunities related to cell lines.

Featured article

Read “Cultivated meat: research opportunities to advance cell line development”

GFI resources

Dig into open-access resources created by our experts.

Expanding access to cell lines

Limited access to cell lines is a significant challenge for cultivated meat research. GFI is working to expand access and support the development of new cell lines.

Cell line development and utilisation trends in the cultivated meat industry

A comprehensive report on the utilisation and advancement of cell lines in the cultivated meat industry, including practical measures for meeting future demands for cell lines and characterisation requirements, as well as regulatory concerns.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate cell line development for cultivated meat.

Research opportunities

Explore research opportunities in cell lines from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

Cell line development from food-relevant aquatic species

A lack of publicly-available cell lines from relevant species and cell types continues to be a challenge for the field of cultivated seafood. Addressing this challenge will require further investigation…

-

Cultivated

Mapping animal cell metabolism to optimize media formulation

The cost and environmental impact of cultivated meat are driven by the cell culture media formulation and its conversion efficiency into meat. Metabolic modeling and engineering techniques can aid media…

-

Cultivated

Promoting stemness and proliferation in fish cell cultures

Efficient and cost-effective cultivated fish production will require precise optimization to encourage fast proliferation and highly efficient use of inputs while preventing premature differentiation. A variety of strategies can be…

Cell culture media

Cell culture media contains the nutrients and growth factors cells need to grow outside the body. Research on optimized formulations, recycling technologies, and scaled supply chains of animal-free, food-grade components is needed to further reduce the costs of cell culture media.

What’s in cell culture media?

The cell culture media is the most important factor underlying the near-term success of the cultivated meat industry. Cell culture media is composed of two groups of components tailored to a specific cell or species type.

The first group of components, called the basal media, provides essential nutrients. It typically consists of a buffered solution containing glucose, inorganic salts, water-soluble vitamins, and amino acids. The second is a group of specific added factors that permit cells’ long-term maintenance, proliferation, or differentiation. These added factors are often recombinant proteins, growth factors or hormones, and other ingredients such as lipids and antioxidants.

Animal serum will not be used in large-scale production

While the basal media has remained nearly unchanged since the 1950s, many industries are still transitioning away from added factors originating from animal sources, such as serum. The use of animal-derived components in cultivated meat production has prohibitive economic and ethical constraints. Many companies have already publicly stated they are using medium formulations that are entirely animal-free, and several research groups and companies have published their protocols for serum-free proliferation and differentiation.

In Singapore, GOOD Meat’s first cultivated chicken products were produced using small quantities of fetal bovine serum (FBS). However, the company received approval to sell cultivated chicken using serum-free media in early 2023. Additionally, Vow’s cultivated quail product, currently sold in Singapore, is produced without serum. In the United States, UPSIDE Foods submitted information to the FDA showing their product can be created with or without FBS.

Here is a summary of the progress made in developing serum-free media formulations and eliminating serum from commercial production.

Cell culture media challenges

Significant cost reductions are possible without large technological leaps

The largest challenge the cultivated meat industry faces is not simply foregoing animal components in the cell culture media but rather discovering how to do so affordably and how to optimize affordable formulations for maximized productivity.

Media cost reduction models have projected achievable prices of less than $0.25 per liter using existing technologies. This would amount to upwards of a 99.9 percent cost reduction versus media manufactured and sold to the biomedical and biopharmaceutical industries—a seemingly daunting task.

However, considerable progress has already been made in achieving these dramatic cost reductions. For instance, a team of researchers at Northwestern University demonstrated that a popular stem cell medium formulation could be produced for 97 percent less than its commercially sold counterpart. Several cultivated meat companies have since claimed that their media costs are already below $1 per liter, with one company publishing a study showing that their serum-free media costs $0.63 per liter.

Reducing the costs of recombinant proteins is the largest price reduction lever

Multiple cost reduction options are being pursued across the industry. The most urgent action is to address the high costs of recombinant proteins and growth factors. While some B2B manufacturers are scaling the production of proteins and growth factors using microbes, fungi, or plants as expression systems, others are looking to replace these proteins and growth factors with plant-based alternatives, especially for proteins used at high concentrations in the media, such as albumin and transferrin.

Costs can also be reduced by sourcing media components at food or feed grade, reducing the overhead and operational costs of producing pharmaceutical-grade components. This will be especially important for amino acids and glucose, which together are predicted to be a longer-term cost driver for media. Some cultivated meat companies have already partnered with various food and animal feed manufacturers to obtain these components by tapping into mature supply chains.

Demand forecasts can help to predict industry needs

Projections of total volumes and demand forecasts for specific media components are needed to inform suppliers, businesses, and investors of the cell culture media market. One study estimated the volumes and costs of growth factors for the industry by 2030, but more are needed for other cost-heavy media components such as amino acids.

Identifying formulations best suited for each species and cell type used by cultivated meat manufacturers remains challenging. Metabolic models and computationally assisted algorithms can help with formulation discovery and optimization. Life science companies with high-throughput and microfluidic capabilities can also provide services for formulation discovery.

Open-source media formulations will be important in informing the selection, sourcing, and production of raw materials that will be used throughout the industry. While cost is a driving factor, food safety, regulation, environmental impact, and social sustainability implications for farmers and others along the supply chain are all important considerations.

What’s next for cell culture media?

Long-term optimizations will contribute to further cost reduction and sustainability improvements

Additional opportunities for cost reduction and optimized formulations are likely to contribute to the commercial success of cultivated meat over longer time horizons. These include developing novel technologies for medium recycling, valorizing waste streams or metabolites produced by cells, engineering growth factors with improved properties, and researching how cell culture media components influence the nutritional profiles of end products. Progress in these areas will require more public funding and co-developing solutions with participants from academia, the food and life science industries, and the cultivated meat industry.

Check out additional reading and resources

Discover papers, resources, ongoing research projects, and research opportunities related to cell culture media.

Featured article

Read “Exploring cost reduction strategies for serum free media development” published in the Science of Food journal.

GFI resources

Dig into open-access resources created by our experts.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate advances in cell culture media.

Research opportunities

Explore research opportunities in cell culture media from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

High-performance oxygen carriers for cultivated meat

Mammalian cell culture performance can be limited by oxygen and carbon dioxide levels or by shear stress associated with sparging and mixing. The use of protein-based oxygen carriers could help…

-

Cultivated

-

Fermentation

-

Plant-Based

Optimizing fat profiles for nutritional and sensory properties

Because alternative meat’s fat content and fatty acid profile can be more easily controlled than conventional meat’s, there is an opportunity to alter fat content for nutritional benefits. Additional research…

-

Cultivated

Mapping animal cell metabolism to optimize media formulation

The cost and environmental impact of cultivated meat are driven by the cell culture media formulation and its conversion efficiency into meat. Metabolic modeling and engineering techniques can aid media…

Bioprocess design

The bioprocess design holds the key to unlocking large-scale production of cultivated meat. Additional research is needed to determine the best bioreactors for different cell types and products, as well as how future facilities will be operated.

The current state of bioprocess design

Bioreactors permit large-scale cell cultivation

The most important aspect of the bioprocess design is the bioreactor. Bioreactors (known colloquially as cultivators) provide the housing and control the conditions that enable cells to grow. For instance, bioreactors control the temperature, oxygen levels, and delivery of cell culture media.

Bioreactors also enable the monitoring of other important parameters, such as metabolite levels, pH, and biomass accumulation. Different types of bioreactors have long histories in other industries that rely on animal cell culture. At present, many cultivated meat manufacturers use existing bioreactor models, while exploring modifications to simplify their design and make them more cost-effective.

Innovations in bioreactor technology represent a large whitespace opportunity

Current models of bioreactors are not necessarily optimized for cultivated meat production. This is because the bioreactor and overall bioprocess design are influenced by the selection of cell type and its properties (e.g., anchorage dependence), the cell culture media cost and composition, and the intended end product.

While some aspects of proliferation and differentiation overlap with other industries, cultivated meat manufacturers must optimize those operations efficiently at massive scales and very low costs throughout the process. This suggests that novel bioreactor and facility designs may be pursued in the cultivated meat industry.

Funding and consortia focused on bioreactors and process scale-up have begun to mobilize

Discovering how to modify existing bioreactors or design new ones is an active research area. In industry, several patents consider bioreactor modifications or improved designs, while B2B companies aim to develop customized bioreactors for cultivated meat manufacturers, including those that operate continuously.

Multiple companies and other stakeholders have formed the Cultivated Meat Modeling Consortium, which aims to apply computational modeling techniques to answer questions related to bioprocess design that may otherwise be overly resource- or time-intensive to pursue. Additional collaborations between cultivated meat manufacturers, life science companies, food manufacturers, and researchers experienced in fermentation and bioprocess scale-up may accelerate R&D in this area.

Bioprocess design challenges

Pilot-scale facilities represent the first major scale-up progress

Scaling up cultivated meat occurs in several separate phases: R&D, bench-scale, pre-pilot, pilot, industrial, and commodity scale. Many companies are currently moving into pilot-scale facilities, where bioreactor volumes can range from approximately 100 to 1000 liters, with at least one company reaching 15,000 liter volumes by the end of 2024. As cultivated meat companies move beyond pilot facilities, they will face the challenge of designing efficient, fit-for-purpose bioprocesses that can either scale up to sizes that dwarf existing animal cell culture facilities or scale out using portable processes and facility designs.

Funding open-access techno-economic models and facility blueprints, with an eye toward regulatory and sustainability considerations, can provide insights into potential bottlenecks for these facilities. Once achieved, a menu of flexible financing options for the large capital expenditures for future facilities will be needed. The formation of co-development manufacturing organizations (CDMOs) may also assist cultivated meat manufacturers by removing technical, financial, and capacity burdens.

Planning for success

Research into other aspects of the bioprocess design will also be important. Cultivated meat manufacturers must be equipped with state-of-the-art sensor equipment, ideally integrated into the bioreactors themselves. These sensors can collect numerous continuous data points, enabling machine learning and artificial intelligence to aid in process optimization. Companies must also develop processes amenable to automation, medium recycling, and waste stream valorization to maximize efficiency. Maintaining sterile cultures in a food-grade facility will also be crucial to success.

The differentiation, maturation, and harvesting of cells for cultivated meat will likely require unique innovations and bioreactor designs that address specific challenges for each phase. Success in these areas may be bolstered by interdisciplinary groups of biologists and engineers with access to research centers equipped with pilot-scale capabilities that can serve as a testing ground for new technologies.

These research centers may be backed by government funding or by joint ventures between academic, food, and biotechnology industry stakeholders, such as the Cultured Hub in Switzerland, which offers pilot plant scale-up services thanks to a partnership between Givaudan, Bühler, and Migros. Other examples include Cultivate at Scale in The Netherlands, supported by the Dutch National Growth Fund, the $30 million Bezos Centers for Sustainable Protein, and a $2.1 million Massachussetts state grant to Tufts University to establish pilot-scale infrastructure. Further buy-in from governments around the world will be crucial for accelerating the commercialization of cultivated meat.

What’s next for bioprocess design?

Innovative bioprocess and facility designs will be needed to support the growth of the cultivated meat industry beyond the next decade. Producing volumes that capture just 1 percent of the global meat market will require extensive new infrastructure that governments, multinational corporations, meat and life science industry incumbents, and a diverse and interdisciplinary workforce can support.

A maximized positive impact on the planet will also depend on future facilities being co-located near renewable energy sources. Other important aspects include easy access to raw materials, equitable job opportunities across rural and urban economies, and product access not limited to wealthy nations.

Check out additional reading and resources

Discover papers, resources, ongoing research projects, and research opportunities related to bioprocess design.

Trends in cultivated meat scale-up and bioprocessing

This report presents findings from a 2022-2023 survey of 30 cultivated meat industry stakeholders and covers current capabilities, future needs, bioprocessing, facilities, equipment costs, and food safety practices.

CE Delft LCA/TEA

A life cycle assessment (LCA) and techno-economic assessment (TEA) show that by 2030, cultivated meat could have lower overall environmental impacts, a smaller carbon footprint, and be cost-competitive with some forms of conventional meat.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate advances in bioprocess design for cultivated meat.

Research opportunities

Explore research opportunities in bioprocess design from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

High-performance oxygen carriers for cultivated meat

Mammalian cell culture performance can be limited by oxygen and carbon dioxide levels or by shear stress associated with sparging and mixing. The use of protein-based oxygen carriers could help…

-

Cultivated

Developing scalable, fit-for-purpose bioreactor and bioprocessing technologies for cultivated meat

Optimizing bioreactor and bioprocessing technologies for the needs of the cultivated meat industry has the potential to substantially reduce the cost of cultivated meat production. Innovations in cultivated meat bioprocessing…

-

Cultivated

Scaffolds and structural approaches to optimize fat distribution and content in cultivated meat

The inclusion of fat and marbling in cultivated meat is likely to increase its flavor, texture, and consumer appeal. Structural approaches using edible microcarriers, hydrogels, and 3D bioprinting present promising…

Scaffolding

Scaffolding provides structural support for cells to adhere, differentiate, and mature, making it crucial to create structured meat products like steak. More research is needed to uncover the best materials and methods for constructing different types of cultivated meat products.

The current state of scaffolds

What do scaffolds do?

The development of scaffolds for cultivated meat requires expertise in fields such as cell biology, biochemistry, materials science, and tissue engineering, with a focus on the role of the extracellular matrix. Many of the tools and techniques developed by tissue engineers for biomedical applications are now being applied to cultivated meat.

Scaffolds must provide access to oxygen and nutrients and have material properties (e.g., mechanical or biochemical) compatible with the cells housed within them. Together with the cell culture medium, scaffolds can dictate how cell populations grow and differentiate. In some instances, scaffolds are used as microcarriers to aid the proliferation of anchorage-dependent cells in suspension bioreactors.

What properties do scaffolds have?

The most likely materials to be used for cultivated meat will be abundant, affordable, and food-safe. Some examples include polysaccharides such as chitosan, alginate, or cellulose; proteins such as zein; or complex composites such as lignin or textured vegetable protein.

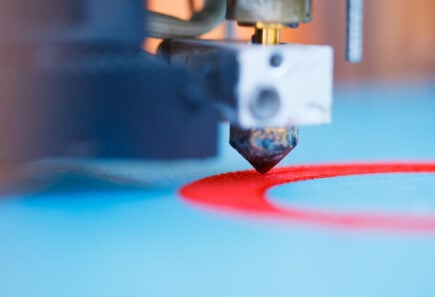

The materials can be assembled using existing techniques, including 3D printing, polymer spinning technologies such as electrospinning, decellularization, tunable hydrogels, or even by nature itself (e.g., fungal mycelium). Several B2B companies, distinguished by their selection of material or method of assembly, aim to supply the industry with scaffolds. Many others are likely to be founded.

The selection of a scaffold and its properties will depend highly on the final product, with scaffolds playing an increasingly important role in more structured products. Scaffolds may be intentionally designed to be rapidly biodegradable, replacing them with native extracellular matrix by the time a product is harvested. Alternatively, scaffolds can make up a substantial portion of the final product, creating a hybrid product.

Scaffold materials that end up in a final product must meet requirements for how that product may be cooked and prepared, as well as how the material influences the product’s safety, digestibility, taste, and nutrition. Public databases of biomaterials and their properties can inform the selection of the most promising scaffold materials and methods to construct them.

Scaffold challenges

Structured products present numerous challenges

The production of thick tissues remains challenging because all cells must lie within a short distance of nutrients and oxygen. There are two approaches to this challenge: a top-down approach, where a prefabricated, porous scaffold becomes infused with cells, or a bottom-up approach, where small, modular units of scaffolds and cells are constructed into a final shape. Both approaches currently exist at small scales, with more research needed to understand the limitations of scaffolding technologies. These data will inform which scaffolds may be best suited for large-scale, commercial production of structured cuts of cultivated meat.

As previously described, the large-scale production of cultivated meat will rely on bioreactors. While microcarriers have been used extensively in other industries, understanding how different types of scaffolds may be incorporated into specialized bioreactors is in its infancy. Given certain fluid flows in different bioreactor models, computational modeling may assist in selecting a scaffold’s material, shape, or topography. Techniques to harvest scaffolds without damaging the cells or tissues will also be important.

Creative solutions are needed

Other methods may use biomaterials to house cells in 3D microenvironments, providing structural support but allowing self-organization principles to govern their behavior within the material. These 3D microenvironments can be formed as spheres, tubes, or other shapes tailored to cell type, placed in bioreactors where they may have specific advantages (e.g., protection from shear stress), and constructed into complex shapes using bottom-up approaches. Similar outside-the-box strategies can contribute to our understanding of structured product creation.

What’s next for scaffolds?

Maximizing potential

The holy grail of the cultivated meat industry is to produce a complex meat product, such as a steak or chicken breast, in a pre-programmed way each and every time. However, current technologies cannot yet accomplish this feat. Significant advances in tissue engineering techniques will be needed to commercialize structured products at scale. Additional challenges lie in discovering the methods and materials most amenable to large-scale production.

Check out additional reading and resources

Discover papers, resources, ongoing research projects, and research opportunities related to cultivated meat scaffolds.

Featured paper

Read the review “Scaffolding biomaterials for 3D cultivated meat: prospects and challenges” by GFI scientists published in Advanced Science.

Explore career pathways in the cultivated meat field

Watch the reimagining meat: pathways for tissue engineers in the cultivated meat field webinar that aims to illuminate cutting-edge career and research opportunities for tissue engineers in the emerging field of cultivated meat. You will hear from Dr. Elliot Swartz, Lead Scientist in Cultivated Meat at The Good Food Institute, and Dr. Ali Khademhosseini, Director & CEO of the Terasaki Institute.

Watch the reimagining meat: pathways for biomedical engineers in the cultivated meat field webinar that illuminates cutting-edge career and research opportunities for biomedical engineers in the field of cultivated meat. Dr. Simone Costa, Associate Director of Strategy & Innovation at The Good Food Institute, and Dr. Ali Khademhosseini, CEO at the Terasaki Institute and CEO at Omeat share their professional paths and experiences.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate advances in cultivated meat scaffolds.

Research opportunities

Explore research opportunities in scaffolding from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

Naturally adhesive and edible non-animal scaffolding materials

There is a limited number of edible non-animal scaffold materials that are naturally adhesive for use in cultivated meat production. Identifying a larger and more diverse set of these materials,…

-

Cultivated

Incorporating growth factors into scaffolds to reduce costs and introduce spatial heterogeneity

Growth factors (GFs) can be incorporated into scaffolds as a strategy for both reducing costs and improving product quality of cultivated meat. Open-access research is needed to test the feasibility…

-

Cultivated

Scaffolds and structural approaches to optimize fat distribution and content in cultivated meat

The inclusion of fat and marbling in cultivated meat is likely to increase its flavor, texture, and consumer appeal. Structural approaches using edible microcarriers, hydrogels, and 3D bioprinting present promising…

End product considerations

Some cultivated meat prototypes have been taste-tested, but many sensory characteristics are unknown. Meat scientists and food scientists can use their knowledge to help create a full range of cultivated meat products that compete with or outperform their conventional counterparts in taste, quality, and nutrition.

photo courtesy of UPSIDE Foods

The current state of end products

What might the first generation of cultivated meat products look like?

Many tasty, compelling cultivated meat prototypes have been created, including shrimp dumplings, pork sausages, chicken nuggets, beef steak strips, fish maw, foie gras, and salmon nigiri, to name a few. However, as of 2024, there remain just four approved products, with only a subset of those currently being sold in Singapore and Hong Kong. At such an early stage, key questions remain concerning what other approved products will look like. Will they be structured or unstructured? What are their costs? And how will they be regulated?

The first generation of approved products may look quite different from company to company, but we can likely predict some characteristics. From a technical standpoint, unstructured, minced product types are easier to create. Thus, this form factor will likely represent most of the first generation of products on the market. As previously mentioned, fully structured products will depend on advances in scaffold and bioprocess technologies and will likely arrive on the market later.

Similarly, first-generation products will come at a price premium. One way to offset these costs is by creating a hybrid product where cultivated animal cells are combined with plant-based ingredients. The percentages of each may vary depending on the product’s price, type, and taste profile. For example, the first product approved in Singapore comprised approximately 70 percent of cultivated chicken cells, while the current iteration has just 3 percent. Many companies aim to produce hybrid products, using cultivated animal fats and other cell types as ingredients.

To be granted regulatory approval and be labeled as a meat product, cultivated meat products must have similar nutritional profiles as their conventional counterparts. Most of this data is currently proprietary. However, some studies are beginning to include nutrition analysis and sensory data such as taste and texture. Data on nutrition and food safety can also be found in the safety dossiers submitted by cultivated meat companies to regulatory agencies, which in some jurisdictions are made public at the time of regulatory approval. While some of this data is likely to become more visible alongside product approvals, more open data on nutrition, digestibility, bioavailability, taste, texture, and other sensory attributes is needed to enhance industry transparency.

For a complete summary of end-product characterization data, visit our end product tracker.

End product challenges

Competing on all aspects of meat quality

Replicating all of the features of conventional animal meat using cultivated meat processes is likely to be challenging. For instance, proteins and metabolites that give meat products their color, smell, and cooking properties may be expressed differently in cultivated meats. Additionally, it is currently unknown whether the post-mortem enzymatic events that can influence meat texture occur similarly in cultivated meat products. Added ingredients that aid in the color, binding, and texture of cultivated meat may be needed, similar to plant-based meats.

Meat scientists must characterize the properties of cultivated meat products to discover differences that may exist. Additionally, food scientists must assist in formulating the best products across a range of versatile dishes. Research teams in academia that incorporate faculty from biological science departments together with meat and food science departments can accelerate progress in these areas.

What’s next for end products?

The future is bright

Companies have an extensive toolset available to continue improving upon end-product characteristics. Improvements in nutrition may be possible by tailoring cell culture media ingredients for desired outcomes, such as increased omega-3 fatty acids or higher vitamin and mineral content. Recent studies have also demonstrated tunable levels of intramuscular fat.

If permissible, genetic engineering could remove allergens or molecules linked to cancer risk from certain forms of meat. It could also insert genes that fortify products with vitamin A precursors not found in conventional meats or create personalized nutrition for specific populations.

Consumer research indicates that a majority of consumers are willing to try cultivated meat or even pay a premium. Willingness to try is highly correlated to the amount of information given to consumers about the cultivated meat production process and its benefits compared to conventional meats. Resources with accessible, educational information about cultivated meat, together with industry transparency, will be crucial for adoption.

Tasting is believing. Recently, countries such as The Netherlands have formalized frameworks for taste tests before market approval, and cultivated meat in Singapore is now available in limited quantities in retail, allowing the first-ever chance for consumers to prepare and cook cultivated meat at home. Novel dining experiences and new culinary creations promise to lure in new consumers and redefine how we view our relationship with meat products. Cultivated meat promises to be an ever-evolving industry for decades to come!

Check out additional reading and resources

Discover papers, resources, ongoing research projects, and research opportunities related to end-product formulation.

Cultivated meat end product tracker

Check out our list of published experiments related to cultivated meat end product properties. Each entry in the table corresponds to a figure or table from an item in the literature library and can be filtered according to the property being tested.

GFI resources

Dig into open-access resources created by our experts.

Aggregating data for alternative seafood

Use our open-access databases to explore how scientific taxonomies and evolutionary relationships map onto culinary categories of seafood.

State of the Industry: Cultivated meat, seafood, and ingredients

This report details the commercial landscape, investments, regulatory developments, and scientific progress in the cultivated meat and seafood industry.

Omega-3 ingredient use in alternative meat and seafood products

Discover our report summarizing 2023 survey results on omega-3 ingredient use and future plant-based meat and seafood production needs.

GFI-funded research projects

Learn about ongoing research by GFI grantees to accelerate end-product formulation for cultivated meat.

Research opportunities

Explore research opportunities in end-product formulation from our Advancing Solutions for Alternative Proteins database.

-

Cultivated

-

Fermentation

-

Plant-Based

Consumer and sensory research to guide alternative fish R&D

Consumer and sensory research can help companies and academic researchers better understand seafood consumers’ needs and desires. Understanding consumers’ needs will allow alternative fish researchers to ask and prioritize the…

-

Cultivated

-

Fermentation

-

Plant-Based

Catalog of animal meat flavors

Creating a catalog of molecules responsible for the characteristic flavor of a species will enable alternative protein product manufacturers to create products that more accurately replicate the sensory experience of…

-

Cultivated

-

Fermentation

Cultivated, fermentation-derived, or hybrid surimi

There has been little publicly announced R&D and commercial effort to develop cultivated, fermentation-derived, or hybrid surimi. Compared to other meat products, surimi is likely to be by far one…

Cost

The cost of cultivated meat is the single largest barrier to broad commercialization. Although significant progress has been made in reducing costs, additional research and funding are needed to further lower the cost of media and establish new, large-scale production facilities.

The current state of cultivated meat costs

The beginning of a long journey

In 2013, Mark Post unveiled the first-ever cultivated burger on live television, which took months to produce and was reported to cost $330,000. Since then, thousands of researchers across academia and industry have begun work toward addressing the number one bottleneck to broader commercialization: cost.

While costs have dropped considerably since then, and some products are being served at restaurants, it remains difficult to pinpoint the current average cost of production across the industry. This is because companies are at different stages of development, use different cells and processes, and are still operating on a small scale. As companies move into commercial-scale facilities and more products come to market in the coming years, it will be possible to derive a more accurate estimate of the cost of production. In the intervening time, the impetus is to identify the cost drivers and develop solutions to reduce or eliminate them.

This webinar provides a detailed summary of the cost drivers of cultivated meat production and the field’s progress in reducing them.

Understanding cost drivers

Techno-economic analysis is a method for analyzing the performance of a commercial process. A model, often aided by computer software, is created to simulate manufacturing based on a certain set of key assumptions. A handful of techno-economic analyses for cultivated meat have been performed to date. Because of the early stage of the industry’s development, the models often use different optimistic or pessimistic assumptions, resulting in different conclusions. It’s important not to overly interpret these early models but instead use them as a roadmap for understanding the cost drivers and prioritizing research objectives.

Cell culture media is a major cost driver

Cell culture media has been identified as the largest cost contributor to cultivated meat production. There are two critical sub-contributors to media costs: the growth factors and other frequently used recombinant proteins (e.g., albumin, transferrin, and insulin), as well as the amino acids.

Reducing the cost of these and other components of the cell culture media is expected to happen in two steps. The first step is to source lower-cost ingredients, primarily by switching from pharma-grade to food-grade components. Since many of the ingredients used in media are common nutrients, they can already be sourced at food-grade levels, where they have been shown to perform just as well as their pharma-grade counterparts. The second step is to use less media and match the media’s nutritional aspects to the metabolic requirements of the cell, resulting in an efficient feed conversion ratio. Metabolic models and artificial intelligence for formulation optimization can aid this step. Some models have estimated that cultivated meat could be nearly three times as efficient as chicken from a feed conversion perspective, although this needs further experimental validation.

Overall, the industry has made substantial progress in reducing the cost of media by over 99 percent from a pharma-grade baseline. Several companies have begun to state and demonstrate that their media costs are below $1 per liter, validating a popular early cost model that estimated costs as low as $0.25 per liter. The main challenge in the coming years will be to chip away at the remaining tenths of the last percent while ensuring media is used efficiently by optimizing feed conversion and constructing efficient bioprocesses.

Infrastructure is a major cost driver

Infrastructure is the second largest cost contributor to cultivated meat production. Two important subcontributors to infrastructure are the buildings and the bioreactors within them.

According to one analysis, it would take about 22 times the amount of the current capacity of the global pharmaceutical industry to produce just ~0.4 percent of the anticipated 2030 global meat production volume. Recent survey data suggests that most cultivated meat companies currently operate bioreactor vessels less than two thousand liters in size, making them capable of producing tens to hundreds of kilograms of meat per production cycle (i.e., every two to eight weeks). This means that many bioreactors and new facilities are needed to fill the current capacity gap and bring cultivated meat products from a few restaurant menus to large retailer shelves.

The industry is still learning about the best approaches to cost reduction for infrastructure and bioreactor equipment. The approach can generally be summarized as taking practices from the pharmaceutical industry and adapting them to a food production environment. This means altering facility layouts and operation flows, lowering the cost of equipment installation and labor through design and automation, and engineering bioreactors to meet the specifications and performance attributes for food production. Success in these areas will require combining knowledge from the pharmaceutical and food and beverage industries to establish a new set of best practices for food production by cultivating animal cells.

What’s next for reducing costs?

The cost trajectory of cultivated meat and important process components, such as bioreactors, may look like other recent innovations, such as solar panels, batteries, and electric vehicles. Initially, they started out expensive and out of reach to the average consumer. However, public and private investment in R&D and infrastructure progressively drove their costs down. Supply chains matured, and manufacturers learned how to produce them more efficiently, dropping the cost by 20 to 30 percent with every doubling of production capacity. After just a few decades, solar panels are now more cost-efficient than fossil fuels, and batteries and electric vehicles are hitting inflection points of adoption.

Like the technology stack for renewable energy, cultivated meat infrastructure is capital-intensive. The investment size needed to build a single commercial facility — in the dozens to hundreds of millions — is now maturing beyond the means of venture capital and will need to tap into larger capital pools. Governments will play a larger role in offering loans or offtake agreements, shaping policies that incentivize industry growth, and developing training programs for job creation. All of this must also happen alongside establishing and maturing a new supply chain.

Creating an entirely new industry does not happen overnight. But, governments are beginning to prioritize cultivated meat for food security, meeting climate goals, or reducing other externalities associated with animal agriculture. If the pace of support accelerates alongside scientific and engineering innovation, the cost of cultivated meat production will be dramatically reduced in the years to come.

Check out additional reading and resources

Discover papers and resources related to cultivated meat costs.

Cost drivers of cultivated meat production

Publications

Environmental impact

Cultivated meat is anticipated to have significant environmental benefits from reduced land use, air pollution, and eutrophication due to its more efficient production. Renewable energy can ensure that cultivated meat is a more sustainable option compared to all conventional meats.

Cultivated meat’s environmental impacts

Life cycle assessment (LCA) is a method for analyzing the environmental impacts of a commercial process through its entire life cycle, including the upstream raw materials that enter the manufacturing process. Similar to techno-economic analysis, LCA relies on a model, often aided by computer software, to simulate manufacturing based on a certain set of key assumptions. Numerous LCAs have attempted to assess the environmental impacts of future cultivated meat production. Although there are still gaps in understanding the impact at commercial scales, studies largely agree on the impact drivers and sustainability benefits of cultivated meat.

Greater efficiencies underlie environmental benefits

Cultivated meat is estimated to be nearly three times more efficient at converting feed into meat than chicken production — the most efficient form of conventional meat. From a caloric perspective, this means that it is estimated that cultivated meat would require between three to four calories of feed for every calorie of cultivated meat produced, although further experimental validation of these numbers is needed. This is possible because cultivated meat avoids calories expended by the animal going about its daily life, cultivation time is shorter than an animal’s life from birth to slaughter, only the cells needed for meat are being cultivated, and manufacturers have more control over optimizing feed conversion by tuning a cell line’s metabolism and selecting complementary feedstocks.

This efficiency translates to cultivated meat requiring 64 to 90 percent less land, and causing 20 to 94 percent less air pollution, 69 to 98 percent less acidification of soils, 75 to 99 percent less marine eutrophication, and similarly sized reductions in some other environmental impacts compared to conventional chicken, pork, and beef production, respectively. Essentially, when fewer crops need to be grown as feed, the result is less land, fertilizer, and pesticides for meat production.

Furthermore, with a massive decrease in land use, additional opportunities arise for carbon sequestration through reforestation, renewable energy production, or biodiversity protection on reclaimed land. Therefore, cultivated meat’s climate benefits are likely far greater than the direct climate impacts measured by existing LCAs.

The carbon footprint of cultivated meat production

According to the most detailed LCA to date, cultivated meat is expected to have a lower carbon footprint than beef and some forms of other conventional meat production when conventional energy is used. However, cultivated meat produced using renewable energy could reduce the carbon footprint of beef by up to 92 percent, pork by 44 percent, and be competitive with chicken. Notably, this model also assumes that conventional meat would be produced with renewable energy and incorporates optimistic reductions in carbon footprints from conventional systems.

The vast majority of cultivated meat’s carbon footprint comes from electricity use at the production facility, thus categorizing them as scope one and two emissions. Compared to plugging into an average electricity grid today, cultivated meat manufacturers can reduce their carbon footprint by about 70 percent through single actions such as using and sourcing renewable energy at their facilities. This is in contrast to conventional meat production, where emissions are more distributed amongst land use change and other greenhouse gases such as methane and nitrous oxide, making them more difficult to reduce through single actions.

Cultivated meat is developing as the world undergoes a global energy transition. Like electric vehicles, as energy grids get greener over time, cultivated meat’s carbon footprint will fall faster than what is achievable in conventional meat production systems.

Sustainability challenges

Environmental impact drivers

The studies that have been performed to date clearly identify the drivers of cultivated meat’s environmental impact. These include the amount and sourcing of energy used at the production facility, the sourcing and production of inputs in the cell culture media, and the efficiency of media use. Identification of these three categories enables manufacturers and suppliers to hone in on the largest levers for sustainable production.

The good thing about these three categories is that incentives are aligned — doing right by the environment is also doing right for a manufacturer’s bottom line. In most parts of the world, renewable energy is already more affordable than fossil fuels, aligning lower utility costs with a lower carbon footprint. Similarly, the efficiency and sourcing of media inputs also play a critical role in costs. Using fewer media ingredients saves costs, lowers the carbon footprint, and uses less land.

Closing the gaps

Early LCAs have provided a solid foundation for understanding the environmental upside of cultivated meat and the areas of focus for the industry to limit the impact. Researchers can refine this information by conducting future LCA studies on hybrid products, exploring the environmental differences between cultivated seafood and cultivated meat, cultivating fat versus muscle cells, different manufacturing processes, different sources of media inputs (e.g., algae, crops, and agricultural sidestreams), and the carbon opportunity of protein production on less land.

Collaboration amongst companies, suppliers, academic labs, and environmental scientists is needed to provide more robust data on bioreactor equipment, amino acids, and other media input production that can be housed in public LCA databases. These databases can then feed into publicly accessible tools that calculate environmental impacts, making the data more accessible to companies, scientists, and policymakers around the world.

What’s next for reducing environmental impact?

Animal agriculture accounts for between 15 to 20 percent of global greenhouse gas emissions and uses about three-quarters of the world’s agricultural land. The scientific consensus states it is impossible to limit warming to 1.5ºC under the Paris Agreement without significantly lowering animal agriculture’s footprint. As the cultivated meat industry matures, country-level LCAs can help guide policymakers to fit cultivated meat in their country’s climate action plans, which may include investments and incentive mechanisms for infrastructure, educating farmers on how to take advantage of local crops for media inputs, ensuring a just transition in rural and urban regions, and how to steward the land to maximize biodiversity protection and carbon sequestration.

Check out additional reading and resources

Discover papers and resources related to the environmental impact of cultivated meat.

Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030

Read the paper “Ex-ante life cycle assessment of commercial-scale cultivated meat production in 2030.”

The environmental impact of cultivated meat production

Watch the lecture “Environmental impacts of cultivated meat production” by Dr. Elliot Swarz, Principal Scientist in Cultivated Meat at GFI and Pelle Sinke of CE Delft.

Resource

Environmental impacts of alternative proteins

Explore the environmental advantages of alternative proteins in diversifying the global food supply. With minimal land and water use, lower GHG emissions, and reduced pollutants, investing in alternative proteins ensures…

Meet the authors

Elliot Swartz, Ph.D.

SENIOR PRINCIPAL SCIENTIST, CULTIVATED MEAT

Elliot Swartz analyzes scientific progress and bottlenecks in cultivated meat.

Areas of expertise: cultivated meat: cell culture media, costs, and environmental impact

Claire Bomkamp, Ph.D.

SENIOR LEAD SCIENTIST, CULTIVATED MEAT & SEAFOOD

Claire Bomkamp is focused on cultivated seafood and driving forward GFI’s Sustainable Seafood Initiative.

Areas of expertise: the science and technology of cultivated seafood, cultivated seafood startups, research, and university programs, scaffolding, science communication, fish puns.