Project aims

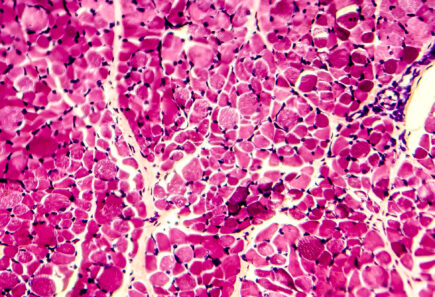

This project will work to develop a biofabrication strategy that enables rapid alignment and maturation of muscle cells. The project also incorporates intramuscular fat compartments and reinforcing fibers to biomimic thick cuts of meat. The outcome would provide a low-cost, high-throughput technology for creating thick cuts of cultivated meat with the appropriate sensory characteristics via better textural design.

Principal researchers

Dr. Mohamadmahdi Samandari

Postdoctoral research fellow, University of Connecticut Health Center, USA

Dr. Samandari has experience researching the interface of biomechanics, microfluidics, and tissue engineering. Currently, he is integrating microfluidic technologies with biomaterials and biofabrication to develop effective bioinks and bioprinting strategies for enhanced myogenesis in vitro and in vivo.

Dr. Ali Tamayol

Associate Professor, Department of Biomedical Engineering, University of Connecticut, USA

Dr. Ali Tamayol is an Associate Professor of Biomedical Engineering at the University of Connecticut Health Center. His research is translational and focused on developing tools that facilitate the treatment of musculoskeletal and skin injuries as well as addressing other unmet needs such as food scarcity. He is currently leading multiple federally funded projects involving skeletal muscle tissue engineering. Dr. Tamayol will work closely with Dr. Samandari for characterization of bioprinted constructs, cellular behavior, extraction of primary cells and their co-printing.

Dr. Olivier Pourquié

Professor, Department of Genetics, Harvard Medical School, USA

Dr. Olivier Pourquié is a Professor of Development Biology and Genetics at Harvard Medical School. He is an expert in muscle physiology and development. Dr. Pourquié will provide insight on the characterization of cellular growth, fate, and differentiation.

Dr. Razieh Farzad

Assistant Professor, Department of Food Science, University of Florida USA

Dr. Farzad is an Assistant Professor of Food Science with expertise in cell-line development and food quality characterization. She will provide insight on the quality of the protein expression in the cultured products and characterization of the meat quality.

Controlling cellular organization in bioprinting through designed 3D microcompartmentalization

Check out Dr. Samandari’s peer-reviewed paper for more detailed information about the biotechnologies being utilized in this research project.

View related grant projects

Biomanufacturing scaffold-free cultivated meat

Learn about Dr. Yuguo Lei’s research to develop an integrated solution for biomanufacturing large-volume cultivated meat at Penn State.

Assembling organoids into meat

Learn about Dr. Iftach Nachman’s research to assemble skeletal muscle organoid building blocks into thick whole-cuts at Tel Aviv University.

Co-culturing cells

GFI grantee Dr. Mariana Petronela Hanga is researching culturing different cell types at the same time.

Designing cost-effective bioreactors

Learn about Dr. Marianne Ellis’s work at University of Bath to reduce the cost of bioreactors for cultivated meat production.

Explore research opportunities

-

Cultivated

High-performance oxygen carriers for cultivated meat

Mammalian cell culture performance can be limited by oxygen and carbon dioxide levels or by shear stress associated with sparging and mixing. The use of protein-based oxygen carriers could help…

-

Cultivated

Developing scalable, fit-for-purpose bioreactor and bioprocessing technologies for cultivated meat

Optimizing bioreactor and bioprocessing technologies for the needs of the cultivated meat industry has the potential to substantially reduce the cost of cultivated meat production. Innovations in cultivated meat bioprocessing…

-

Cultivated

Scaffolds and structural approaches to optimize fat distribution and content in cultivated meat

The inclusion of fat and marbling in cultivated meat is likely to increase its flavor, texture, and consumer appeal. Structural approaches using edible microcarriers, hydrogels, and 3D bioprinting present promising…

Check out related resources

The science of cultivated meat

Learn about the science of cultivated meat and the challenges that must be addressed for commercial production.