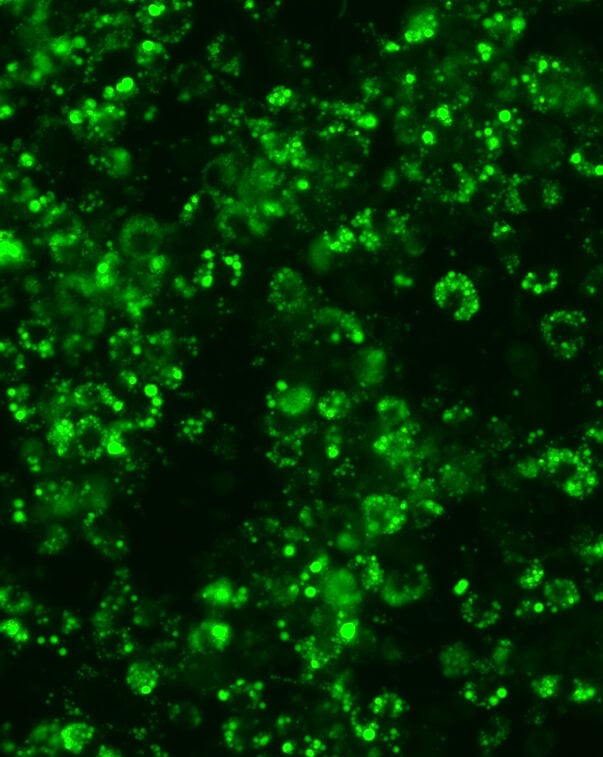

Co-culturing cells

2019-2021

Dr. Hanga is co-culturing cells to advance the production of cultivated beef towards commercialization.

PRODUCTION PLATFORM: Cultivated

TECHNOLOGY SECTOR: Bioprocess design

Project aims

This project uses small bioreactors to produce high-density stem cell cultures in suspension. It develops parallel one-step bioprocesses for culturing different types of cells – both adipocyte and myocyte lineages. By employing hydrogels for cell encapsulation to co-culture differentiated cells, the research seeks to produce complex microtissues in small bioreactors.

This work paves the way for pilot-scale bioreactors that produce complex cultivated meat products. It also identifies topics to be addressed in bioreactor scaleup through a cost analysis.

Principal researcher

Dr. Mariana Petronela Hanga

Lecturer in Biological Engineering, Aston University, UK

Dr. Hanga researches stem cell bioprocessing, human mesenchymal and induced pluripotent stem cells, bioreactor scaleup, and cultivated meat. She produces stem cells and microcarriers for easier cell collection after culturing – specifically, nonenzymatic cell harvesting through either temperature control or microcarrier disassembly.

Bioprocess development for scalable production of cultivated meat

Check out Dr. Hanga’s peer-reviewed paper for more detailed information about this project.

View related grant projects

Integrating sensors into bioreactors

GFI grantees Dr. Ivana Gadjanski and Dr. Vasa Radonic are integrating sensors into bioreactors for cultivated meat production.

Designing cost-effective bioreactors

Learn about Dr. Marianne Ellis’s work at University of Bath to reduce the cost of bioreactors for cultivated meat production.

Computational modeling

GFI grantee Dr. Simon Kahan at the Cultivated Meat Modeling Consortium is using computational modeling to improve bioreactor design for meat cultivation.

Explore research opportunities

-

Cultivated

High-performance oxygen carriers for cultivated meat

Mammalian cell culture performance can be limited by oxygen and carbon dioxide levels or by shear stress associated with sparging and mixing. The use of protein-based oxygen carriers could help…

-

Cultivated

Developing scalable, fit-for-purpose bioreactor and bioprocessing technologies for cultivated meat

Optimizing bioreactor and bioprocessing technologies for the needs of the cultivated meat industry has the potential to substantially reduce the cost of cultivated meat production. Innovations in cultivated meat bioprocessing…

-

Cultivated

Scaffolds and structural approaches to optimize fat distribution and content in cultivated meat

The inclusion of fat and marbling in cultivated meat is likely to increase its flavor, texture, and consumer appeal. Structural approaches using edible microcarriers, hydrogels, and 3D bioprinting present promising…

Check out related resources

This professor is figuring out how to produce, scale, and combine muscle and fat for cell-based meat

Dr. Petra Hanga is working to optimize cell-based meat production by creating a robust and reliable scale-up process for fat and muscle cells.