Naturally adhesive and edible non-animal scaffolding materials

There is a limited number of edible non-animal scaffold materials that are naturally adhesive for use in cultivated meat production. Identifying a larger and more diverse set of these materials, which tend to be inexpensive and accessible, and characterizing their industrial scalability, environmental impact, and effects on food properties supports progress towards cultivated meat price parity.

-

Cultivated

- Scaffolding

Current challenge

Production for some types of cultivated meat, especially products that require complex structure and suitable texture, is expected to rely on scaffolding as an integral input. Scaffolding is not only critical for meeting end product characteristics, but also may be used to increase bioreactor cell densities and productivity (Santos et al. 2023). Despite this importance, there is relatively less attention to this consideration in scaling cultivated meat.

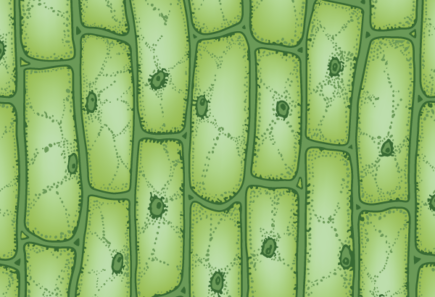

Scaffolding provides a surface for cells to adhere to, which in turn supports cell proliferation, differentiation, and organization due to the mechanical support and enhanced nutrient and waste transportation that the scaffolding structure confers. To realize these attributes, the scaffold must first support adequate cellular adhesion in order to achieve any benefits for cultivated meat production.

There are three primary categories of scaffolding: 1) synthetic polymers (e.g., PEG) (Biswal 2021), 2) ECM and animal proteins (e.g., collagen) (Zernov et al. 2022), and 3) edible non-animal materials (i.e., plant- and fungi-based). Naturally occurring non-animal materials are often edible and offer potential nutritional and price point advantages. However, edible non-animal materials studied to date have shown variable extents of cellular adhesion. More research is required to identify what strength and characteristics of cellular adhesion are required for cultivated meat applications and which edible non-animal material-based scaffolds meet adhesion requirements.

Limited discovery of edible non-animal materials that present adhesion motifs

Numerous peptide motifs that mediate animal cell adhesion such as RGD (Bellis 2011) have been characterized, but many edible non-animal materials such as alginate (Tahir et al. 2022) and bacterial nanocellulose (Rybchyn et al. 2021) lack these motifs, limiting their utility as a scaffold for animal cells.

Functionalizing materials by coating them in adhesive peptides has been previously demonstrated (Chandler et al. 2011), however, this technique is not yet approved for use in food (Bodiou et al. 2020). In the United States, a filing for Generally Recognized as Safe (GRAS) for consumption status could be expected to be successful, but still requires significant time and money investment to clear this regulatory hurdle. Synthetic peptides could similarly achieve a positive GRAS filing outcome, although additional scrutiny on allergenicity would be likely.

The need for naturally adhesive non-animal scaffolding materials

There are also edible non-animal materials that are naturally adhesive and readily facilitate cell attachment without additional functionalization. The exact mechanisms that mediate cellular adhesion are not completely known, although the presence of extracellular matrix and/or adhesion motifs alongside physical characteristics such as pore sizes (Zeltinger et al. 2001) and stiffness (Neves et al. 2020) have been proposed as important factors. Scaffold materials in this class include textured vegetable proteins (Ben-Arye et al. 2020), chitosan (Jana et al. 2012), and decellularized spinach (Jones et al. 2021). There is a need to conduct a broader survey to identify 1) a larger and more diverse set of naturally adhesive food-safe non-animal scaffolding materials, and 2) the mechanisms that govern cellular adhesion for those materials.

Testing of these naturally adhesive edible scaffolding material candidates has been mainly performed in laboratory-scale environments that may or may not represent commercial-scale production environments or needs. For example, while textured vegetable proteins are shown to be naturally adhesive, their native seeding efficiency is low (Lee et al. 2022). More robust characterization is needed to contextualize the performance of these materials in ways that can reliably inform large-scale cultivated meat production (Figure 1).

Proposed solution

Investigating the following three questions has the potential to yield significant progress toward maturing biomaterial scaffolding technology for cultivated meat:

- Which natural edible materials do cells used in cultivated meat production adhere to?

- What are the root mechanisms/motifs by which these mediate adhesion?

- What are the most economical and sustainable sources of these materials?

Here we propose pursuing solutions according to near-term and longer-term methodologies that respect the current and expected future states of the alternative protein industry (Figure 2).

Material candidate screening for minimum viable product

In the near term, we propose that individual companies and research institutions continue to approach screening for minimum viable product(s) (MVP) for their own scale-up and commercialization needs. Considering all three scaffold adhesion elements (Figure 1) in design and freely sharing knowledge across organizations will be key to accelerating progress. There are several examples, considerations, and open research directions that one can use to guide MVP screening:

- Decellularized plant tissues are an example of a class of biomaterials actively being explored from this MVP perspective. A foundation of biomedical literature indicated that decellularized plant tissues are promising for cultivated meat use (Fontana et al. 2017, Mutra et al. 2023). Alternative protein researchers have now begun screening — demonstrating that spinach can be used for cultivated meat without additional functionalization (Jones et al. 2021).

- The cultivated meat industry is beginning to use non-animal proteins to mediate adhesion in otherwise inert scaffolds — like in Modern Meadow’s patent. They produce adhesive scaffolding by crosslinking naturally inert pectin with the adhesion motif-presenting food-grade protein, cardosin A. More research is needed to identify promising naturally sourced food-grade proteins for mediating adhesion.

- Adhesion motif research mainly focuses on integrin binding partners (Bomkamp et al. 2022). Materials likely to contain these motifs could and should be targeted for MVP screening. Considering food-grade materials with different binding partners or unknown binding affinities would also be valuable. This could identify pathways to new adhesion mechanisms and a greater diversity of material options.

- Some exciting and open research directions at the intersection between the three elements governing cellular adhesion (cell type, bioprocessing, end product) include:

- Which metrics are most effective to measure adhesion in a way that translates into cultivated meat utility? Can you develop an assay that scores adhesion relative to some standard benchmark (e.g., RGD)?

- What are the different mechanisms of cellular adhesion and the interplay between them?

- How does the culture environment (including mixing) influence the kinetics and equilibrium of cellular adhesion?

- What is the feasibility of letting cells incubate in an ‘adhesion phase’ with a minimally adhesive scaffold to improve adhesion characteristics? To what extent would the cells be able to deposit their own extracellular matrix to strengthen cellular adhesion for proliferation and/or differentiation phases?

- To what extent does the cellular metabolic state influence adhesion? And what levers can we pull to control this in a controlled production environment?

- What is the orthogonality between different adhesion motifs in conferring adhesion strength and quality for a given cell type? What about in an environment containing a mixture of cell types?

Systematic evaluation for high-volume commercial utilization

Lessons learned during material candidate screening for MVP should inform an evaluation of naturally adhesive food-grade scaffolding materials for high-volume commercial utilization. More resources and a higher level of industry maturity will open up more rigorous approaches to identifying high-efficacy and low-cost scaffolding materials. This systematic and iterative evaluation breaks down into three sequential steps: 1) adhesion motif discovery, which informs 2) scaffold material discovery and eventually leads to 3) commercialization landscape analysis (Figure 2).

Evaluation: adhesion motif discovery

The toolbox of adhesion motifs that mechanistically underpin cellular adhesion can be expanded. Computational methodologies such as molecular dynamics (Wang et al. 2019) and deep neural networks (Motmaen et al. 2023) are getting better at predicting protein-protein interactions. This is also true for predicting unwanted binding interactions (Malinverni et al. 2023) to avoid, which may arise between the scaffold material and non-adhesion-mediating receptors, cell debris, or other ingredients within the cell culture media. These can be coupled with experimental learnings and validation using high-throughput methodologies like peptide array, phage display, and mass spectrometry (Liu et al. 2012).

Evaluation: scaffold material discovery

Proteins containing peptide adhesion motifs of interest can be identified by computationally evaluating known non-animal protein structures. Simple genome mining was recently employed to successfully identify RGD-containing food-safe fungus-derived proteins that support cellular adhesion (Teo et al. 2023). Further selection criteria includes predicted steric and electrostatic availability of the adhesion motifs as a predictor of cellular adhesion efficacy. For example, different attachment orientations of the RGD adhesion motif in a hydrogel scaffold resulted in substantially different human stem cell viability levels (Salinas et al. 2008). Developing high-throughput assays for cell adhesion and other biomaterial properties will be necessary to experimental validate and supplement computational predictions. Biomedical advances in scaffold-based micro-arrays for drug screening provide solid foundations for translation into cultivated meat applications (Zhou et al. 2023).

Evaluation: commercialization landscape analysis

As with the selection of any high-volume commercial pathway, rigorous assessment of the throughput, economic viability, and environmental impact are critical in rigorous food-safe non-animal scaffolding material evaluation. Techno-economic and life cycle analyses are powerful methodologies to this end and have already been used to support cultivated meat development. These assessments should define synergies between scaffold materials and the specific cultivated meat industry needs because the inclusion of a scaffold and differentiation step could impact the overall process design, influencing capital and operational expenditures and, in turn, the environmental impact of production.

For example, are there scaffolds that yield high performance, but only in particular bioreactors or with only specific cell types, with degradation and/or texture profiles that support only specific end products? Sensitivity analyses, including those used to define the minimal concentration of naturally adhesive food-grade material in the scaffold to maintain cellular adhesion, are essential inputs and considerations around these types of landscape analyses. It is also important to consider both the current and future states of development in assessing commercial potential.

Anticipated impact

The general anticipated impacts of plant-based scaffold use in the cultivated meat industry have already been summarized, representative of non-animal-based scaffold use in general. Recent efforts have also shown that non-animal material scaffolds can be prepared from agricultural waste (Perreault et al. 2023), supporting the circular bioeconomy. Non-animal material scaffolds could also represent an opportunity to increase the diversity or utilization of crops grown, which could help farmers and the environment (e.g., scaffolds derived from cover crops). Naturally adhesive non-animal material scaffolds provide opportunities for more straightforward regulatory and more cost-effective manufacturing pathways to cultivated meat commercialization as compared to the functionalization of non-adhesive materials. While many cultivated meat processes are structured around scaffolding, there are also efforts to pioneer scaffold-free cultivated meat. Prioritizing the discovery and development of non-animal material scaffolds for use with end products not likely to be near-term compatible with scaffold-free cultivated meat would maximize return potential.

Related efforts

- Binding Revisited—Avidity in Cellular Function and Signaling (Erlendsson et al. 2021)

- The Kinetics of Cell Adhesion to Solid Scaffolds: An Experimental and Theoretical Approach (Doaga et al. 2008)

- The immobilization of fibronectin- and fibroblast growth factor 2-derived peptides on a culture plate supports the attachment and proliferation of human pluripotent stem cells (Dayem et al. 2020)

- Synthetic Materials that Affect the Extracellular Matrix via Cellular Metabolism and Responses to a Metabolic State (Sthijns et al. 2021)

GFI resources

Deep dive: Cultivated meat scaffolding

Learn about scaffolding materials and methods for cultivated meat.

Meet the author

Matt McNulty

GFI RESEARCH FELLOW

University of California, Davis

Find collaborators

Join the GFIdeas global community of 2,000+ entrepreneurs, scientists, investors, and subject matter experts. Discuss projects on the members-only Slack community, attend monthly seminars, and use the community directory to help you find collaborators working on similar Solutions!

Related solutions

-

Cultivated

-

Plant-Based

Plant-based scaffolds to improve cultivated meat nutrition

A variety of plant-based scaffolds present the opportunity to combine the natural nutritional and structural benefits of plants with the taste and high protein of cultivated meat. Bacterial nanocellulose from…

-

Cultivated

Biomaterials for scaffolding

A handful of companies and researchers are developing scaffold materials for use in various steps of the cultivated meat production process, but to date the topic of scaffolding has been…

Explore the full solutions database

Browse 100+ startup ideas, commercial opportunities, research projects, and investment priorities throughout the alternative protein supply chain.

Get involved

If you’d like to fund a research project, work on any of these solutions, share information about related efforts that are already underway, or elevate new ideas for advancing the alternative protein industry, we’d love to hear from you!