3D microenvironments for cell expansion

Proliferation and high-density cell growth are fundamentally important to scaling cultivated meat production. Recent demonstrations of stem cell expansion in 3D microenvironments such as encapsulated spheres or tubules can generate cell densities far higher than industry-leading stirred tank bioreactors with minimal loss of cell viability or stemness. As a scalable platform, the use of 3D microenvironments for stem cell expansion and differentiation—particularly with the relevant cell types used in cultivated meat—warrants further investigation.

-

Cultivated

- Research

- R&D

- Bioprocess design

- Scaffolding

- Academics

- Industry

- Startups

Current challenge

Efficient systems for proliferation and high-density cell growth are essential for creating the biomass needed for the cultivated meat industry at an economically viable price and scale. Because many cell types used by the cultivated meat industry are anchorage-dependent, their growth requires a solid surface such as microcarriers or the use of cell aggregates. However, both of these approaches present challenges for scale-up and achieving high cell densities in stirred tank bioreactors. The presence of microcarriers can increase shear stress and damage, while aggregates must be carefully controlled to prevent overgrowth. Similarly, adapting cells to suspension growth comes with its own sets of challenges regarding mass transfer of oxygen and nutrients. Innovative, scalable solutions are therefore needed that can permit high-density cell growth in environments with minimized shear stress.

Proposed solution

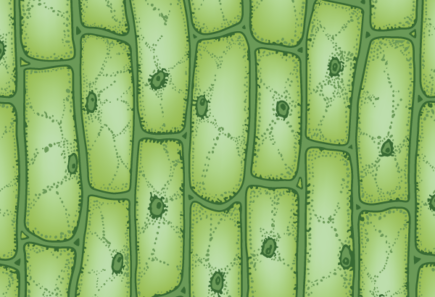

The growth and differentiation of cells in 3D microenvironments offers several advantages over suspension-based bioreactors. First, cells are confined to microenvironments inside permeable biomaterials within 200µm of nutrient access. This prevents the possibility of necrotic cores forming, as in aggregate growth. Second, cell confinement and encapsulation protects them from exposure to shear stress. Therefore, media mixing can be performed more aggressively because it exerts minimal physical effect on the cells. Third, cells have been reported to achieve densities of up to 5×108 cells per milliliter, which is significantly higher than stirred-tank suspension systems or growth on microcarriers. Fourth, the creation of microenvironments using coaxial extrusion to produce tubular structures is scalable and can be performed using low-cost, food-safe biomaterials, including materials like alginate that are already being explored for use in scaffolding. Fifth, differentiation can occur within the same microenvironments and may be enhanced by 3D growth facilitating cell polarity, alignment, and other self-organization traits. The use of 3D microenvironments to culture cell types used in cultivated meat warrants further investigation.

Anticipated impact

The successful demonstration of 3D microenvironments for the cell types used in cultivated meat could fundamentally change the approach of the overall bioprocess, as proliferation and differentiation could occur in a single environment. Because of the inherently self-contained nature of cells grown within 3D microenvironments, it is theoretically possible that even the seed train scale-up process can be avoided or shortened, which could drastically shorten the overall production cycle and improve efficiencies.

Furthermore, fewer transitions for cells may also reduce shock and streamline the bioprocess overall. The possibility also exists for simplified creation of whole-tissue, structured products that can be constructed via additive manufacturing of the differentiated cells within the microenvironments themselves, rather than relying on cell-laden scaffolds. This would open up a whole new approach for the fabrication of complex, multi-cell-type tissues.

Related efforts

3D microenvironment systems for proliferation and differentiation of cells have been created and published. Some examples include:

- Lin et al., 2018

- Li et al., 2018,

- Allen et al., 2017

- Hsaio et al., 2016

- Treefrog Therapeutics has created a stem cell expansion technology using sphere-based microenvironments.

Find collaborators

Join the GFIdeas global community of 2,000+ entrepreneurs, scientists, investors, and subject matter experts. Discuss projects on the members-only Slack community, attend monthly seminars, and use the community directory to help you find collaborators working on similar Solutions!

Related solutions

-

Cultivated

Computational models of perfusion flow through scaffolds

For tissue-structured cultivated meat production, the transition from the proliferation phase to differentiation phase may involve seeding cells onto a prefabricated scaffold within a perfusion bioreactor. Medium is then perfused…

-

Cultivated

Developing assays for meat-specific cell traits

Research to align on the appropriate assays would introduce standardization that can accelerate R&D efforts.

-

Cultivated

Mapping the secretome of animal myoblasts, adipocytes, and other cells used in cultivated meat

Stem cells secrete a variety of signaling factors that can influence the behavior of surrounding cells, known as paracrine signals. In high-density bioprocesses, these secreted factors can accumulate to concentrations…

Explore the full solutions database

Browse 300+ startup ideas, commercial opportunities, research projects, and investment priorities throughout the alternative protein supply chain.

Related GFI research grants

Optimizing media for chicken cells

Learn about Dr. David Block’s work to perfect growth media for cultivated chicken at University of California, Davis.

Cellular building blocks

Learn about Dr. Marcelle Machluf’s work designing cellular building blocks for cultivated meat with at Technion – Israel Institute of Technology.

Plant-based scaffolds

GFI is building plant-based tissue scaffolds for cultivated meat with Dr. Masatoshi Suzuki at University of Wisconsin, Madison

Developing marbled cultivated beef

GFI is developing marbled cultivated beef with Dr. Amy Rowat at University of California, Los Angeles

Get involved

If you’d like to fund a research project, work on any of these solutions, share information about related efforts that are already underway, or elevate new ideas for advancing the alternative protein industry, we’d love to hear from you!